Equipment Introduction

1. Change paper core automatically. The finished roll will be pushed automatically, then change another paper core for rewinding. Many size of paper core are suitable.

2. Adopt PLC programmable controller to control the production. The rewinding process of the product is tight first and loose afterward, with its tension adjustable. The paper core is not easy to loose.

3. Stepless unwinding raw paper to keep it is stable.

4. Jumbo Roll Paper is pneumatically uploaded onto machine. Machine stop when raw paper broke.

5. Perforating knife with 4 pcs to make lower noise. Perforating effect is good. It control by air pressure, easy for paper through.

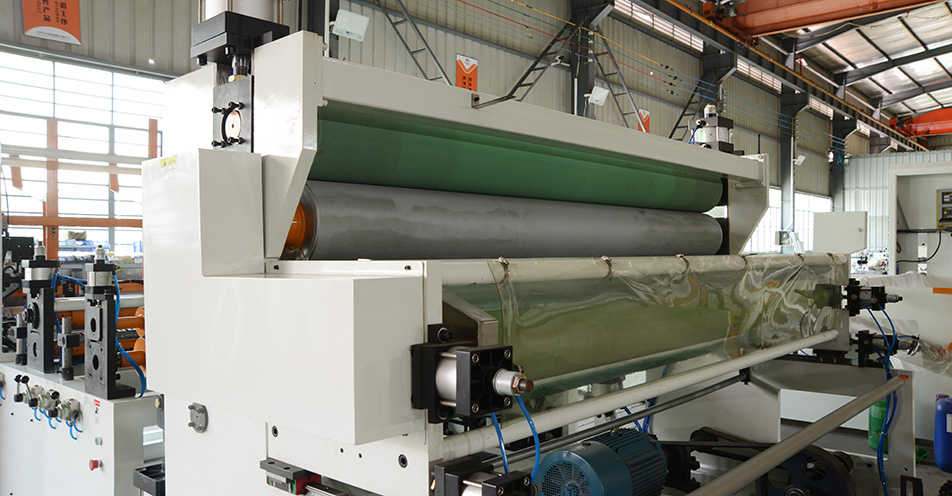

6. Embossing unit is steel to rubber rollers.

7. Glue device: when produce kitchen towel, the glue make two plies of paper stick together to improve water sucking and outlook.

Technical Parameter

| Production speed (m/min) | 150-200 |

| Finished roll diameter (mm) | ≤250 |

| Perforating distance (mm) | 110-250 |

| Jumbo roll width (mm) | ≤2400 |

| Jumbo roll diameter (mm) | ≤1200 |

| Paper core inner diameter for Jumbo roll (mm) | 3′(φ76) |

| Air pressure(Mpa) | 0.5~0.8(air compressor prepared by customer himself) |

| Equipment power(KW) | 15.4 |

| Equipment weight (T) | 7 |

| Equipment overall size(L*W*H) (mm) | 5700*2000*1700 |